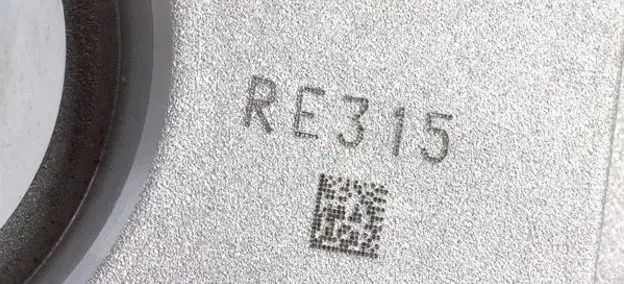

Because it requires clarity and legibility, the engraving depth of the laser engraver is an important attribute required for marking parts. Not all marking systems can boast depth. Of course, the laser engraving depth of Ortur Laser Master 3 will definitely make you satisfied.

Depth and speed are comparative properties, because increasing the depth will reduce the speed of the process. However, it is also possible to speed up the parts marking process without losing depth. HTPOW introduces several methods based on years of laser engraving experience.

Laser Engraving

Laser engraving is a laser marking process that involves using the laser beam generated by a laser marking machine to remove part of the material in order to mark it. By performing the following operations, you can increase the speed of the laser engraving process without sacrificing depth.

Power Supply

The power of the machine determines the speed and depth of marking. Therefore, you should choose a very powerful laser marking machine. For example, Ortur can perform deep engraving without sacrificing speed. Before, we paid attention to the depth of laser engraving, which affects the speed of laser engraving, so they developed and improved the laser engraving ability of Ortur Laser Master 3.

Lens

The lens is the most important parameter that determines the speed of the engraving process. It controls the focus of the laser beam, thereby controlling the intensity and depth of the marking. Using the correct lens can ensure the correct engraving speed. Experts have found that depending on the material, a smaller lens is very useful. effective. Therefore, you should choose a laser marking machine with a smaller lens.

Scan Speed

Scanning speed is the moving speed of the laser beam. When the laser beam moves slowly, the depth will increase because it stays in the same area for a longer time. You should be able to get a machine that achieves a balance between scanning speed and depth. For example LaserPecker 2's laser engraving speed is 36000mm/min, so you can choose to use it for fast regular depth engraving.

Temperature of Parts

Preheating materials can also ensure that you can increase the speed without sacrificing depth. For example, when you heat aluminum parts, you can carve 40% depth at the same time.

Engraving Line Size

Engraving line size is the distance of the laser beam before starting a new one. After each line, there is a small delay called incubation speed (about 0.03 seconds, depending on the machine), it will be timed. The engraving speed is fast. Therefore, you should be able to adjust it according to your project.

Use an Electric Needle Machine

There are mainly two types of point marking machine: pneumatic and electromagnetic. Both provide depth, but the speed of electric point needle machine is faster. For example, HS-PE electric engraving machine is a common, fast and economical industrial select.

Machine Quality

Some machines have industrial capabilities and multiple functions, such as accuracy and durability. The speed of the machine is closely related to its accuracy and durability. Therefore, you should choose machines with these qualities.

Easy to Operate

The operation and control of the point machine mainly consider three aspects: marking software, portability and advanced operation. Make sure you choose user-friendly software, which has the function of making marking easier.

Control

In addition, according to the different parts, you should be able to customize your machine. Because it is easy to operate and control, the portable machine is suitable for large objects. Automatic marking and live body etc. Advanced operation also ensures that you mark quickly without causing problems.

Dash Line

Marking or manual engraving is another common parts marking process that you can use. It involves using a stylus to continuously remove part of the material and form a continuous mark. The only method is to change the marking system. The best choice is laser engraving and point spraying.

Realize the speed and depth of the marking

The deep laser engraving is clearly visible in the bad environment. However, rapid marking is important for production efficiency. In addition to the above discussion on the precise positioning of parts marking. You can also ensure that the marking system is customized for the correct material. 。

Choosing the right marking machine is essential to speed up the marking process of parts without causing problems. Therefore, you should choose a partner with sufficient marking machine experience in the industrial environment. strong industrial capability.